Hi-Tech News

Moving to an Outside IT provider

IT’S ELECTRIC: EMI/RFI Shielding in Thermoplastics

You can still solve part issues after you build a tool

There are three major elements in thermoplastic design. Each is an opportunity to improve production efficiency, end-product performance and quality.

The first opportunity is part design, with material selection being a close second and mold design third. Optimizing the three plastic part design inputs – part design, material and mold design – are the best way to avoid issues.

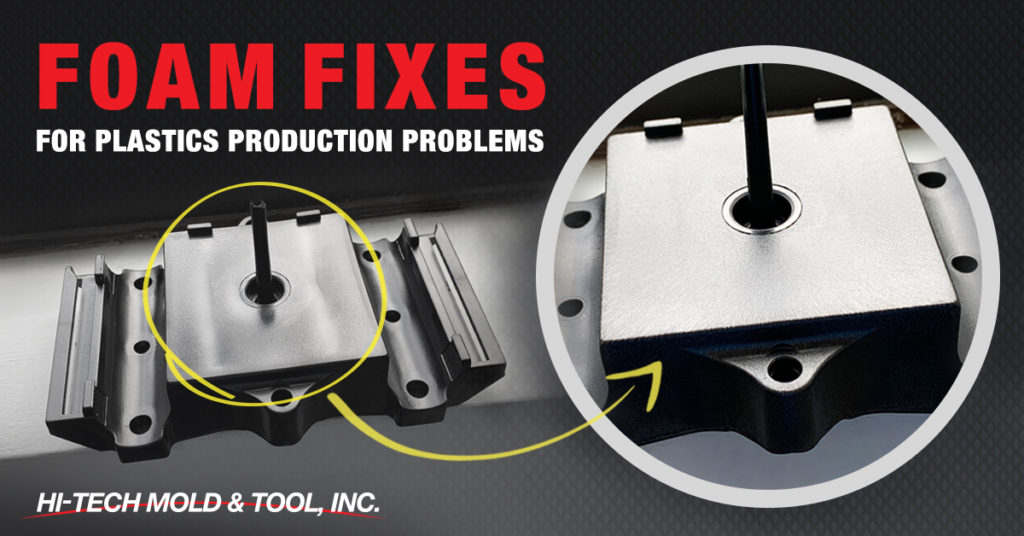

Thermoplastic Part Improvements using a Foaming Agent

Thermoplastics have a lot of good attributes, but they aren’t perfect. Thicker ribs or walls will show sink marks. Surfaces can show the signs of minor impacts or scuffs.

Larger parts with thicker sections require longer cycle times to ensure there is no part deflection upon mold opening. When part designs result in molding issues, chemical foaming agents can be an effective tool to improve the finished product.

Comparison of Off Shore Tooling vs Domestic Tooling

Hi-Tech Mold & Tool, Inc. has our own tool room, so we quote tools that we make. When our customers request it, we’ll work with off shore tooling vendors but Offshore Tool Quotes and Domestic Tool quotes are not the same. Below we’ll outline some differences that we’ve experienced over many years of building and sourcing tools.

Functional Thermoplastics

The aspect of thermoplastics that I’ve always thought is the most interesting is the ability to make thermoplastics more functional. Most thermoplastic applications that are older than 10 to 15 years are applications that utilize thermoplastics as a shell or protective package. Old and new desk telephones use thermoplastic as the shell, as do most portable electronics.

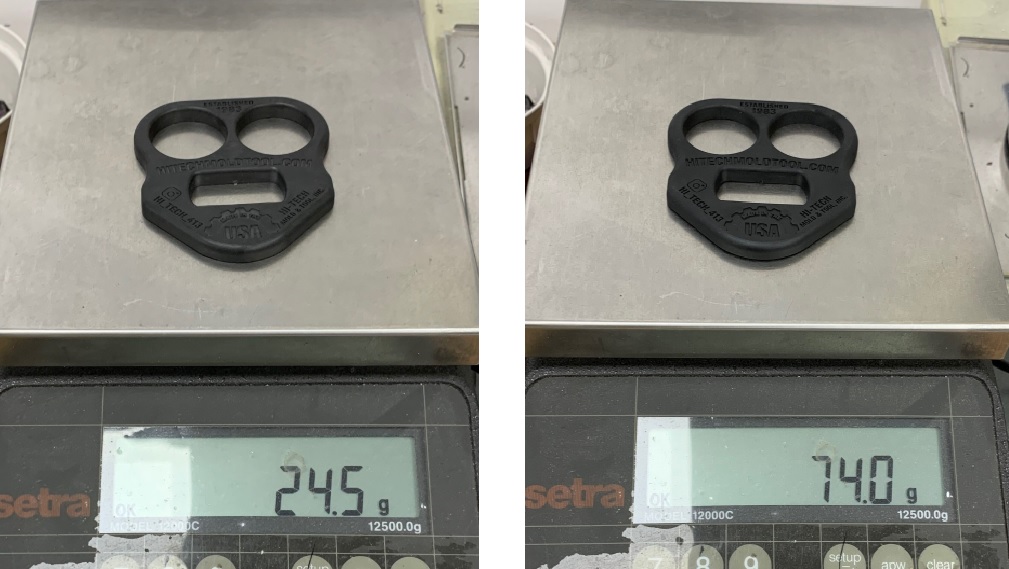

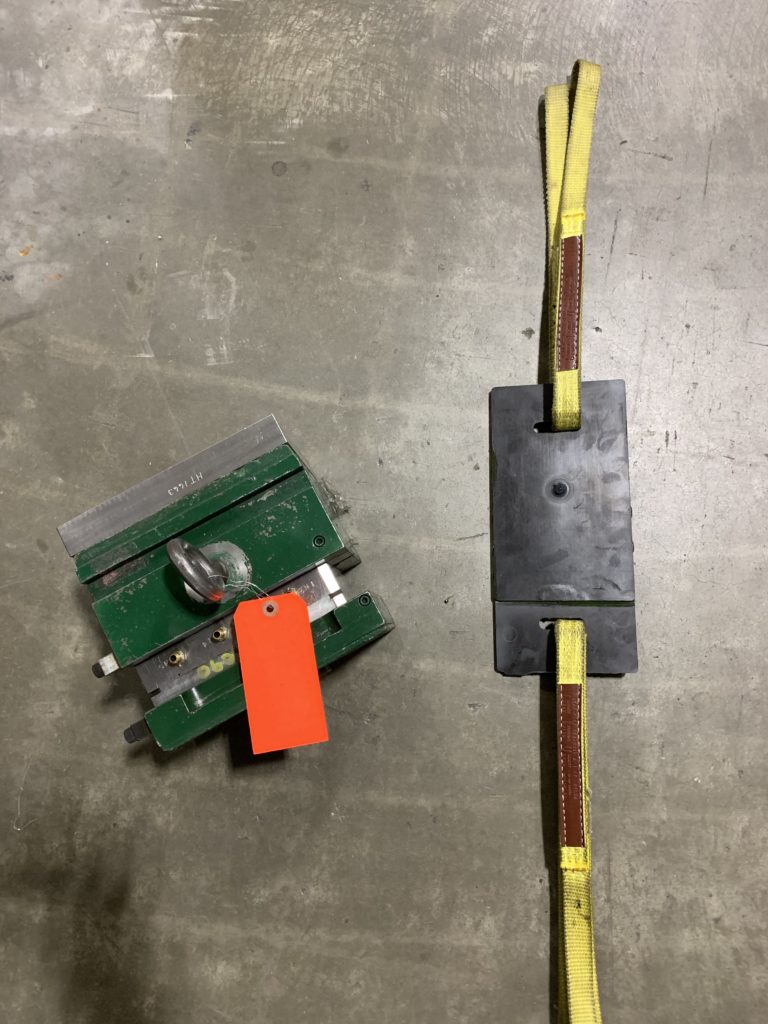

PEEK2PEEK: Carbon Fiber filled PEEK bonded together

Hi-Tech has been bonding Carbon Fiber filled PEEK parts together for over 10 years. We decided to bond two scrap pieces of Carbon Fiber filled PEEK together and run a test to see the largest mold we could lift before the bond failed. Comment if you were surprised.

Why are my plastic parts cracking?

Plastic parts can crack or fail for a variety of reasons. The part could be deformed beyond the mechanical properties of the material causing yield or break issues. Breakage can be characterized by brittle and and ductile mechanical failure. Brittle will typically show a sharp break and ductile will stretch and tear which may include stress whitening. Besides mechanical load based failures, UV may negatively decrease plastic performance over time. Parts may yellow and then crack due to UV exposure. The UV light attackss the polymer bonds

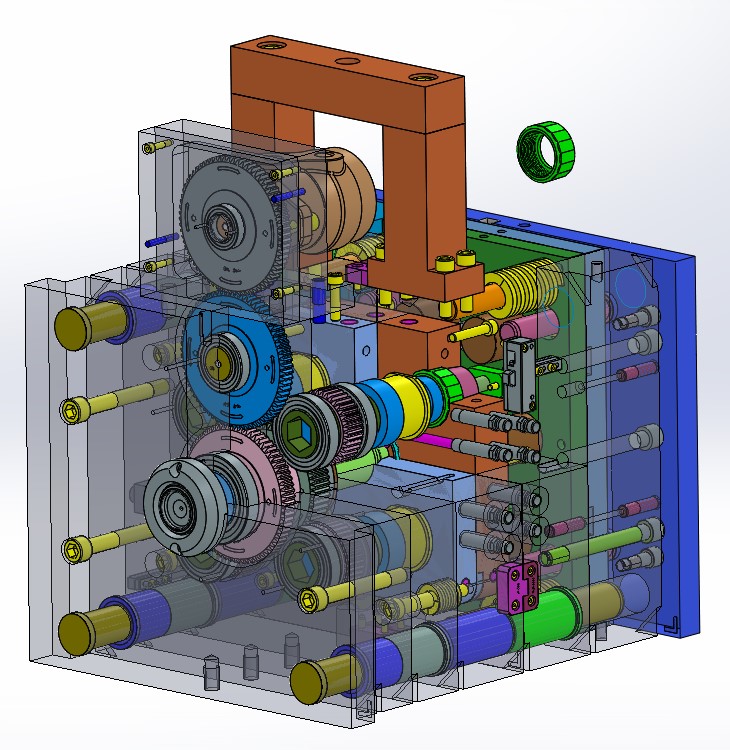

Injection Molding 101: Machine Clamp Tonnage

This is the second of two videos about the basics of Injection Molding. This video reviews the Machine Clamping mechanism.

Our equipment list shows the various injection molding machines at Hi-Tech and they are generally referred to as a 100 ton press or a 500 ton press. This refers to the clamping pressure that the press can deliver.