More Design Options from More Manufacturing Options

Machining metal is commonplace. Plastic Part and Stock Shape machining is a specialty only the most skilled resin craftsmen can attempt.

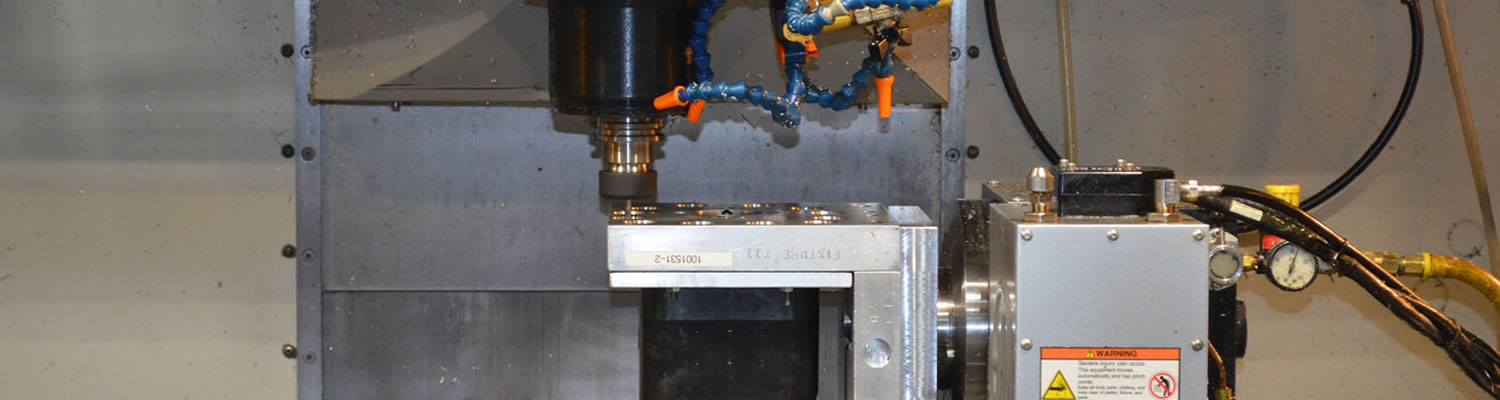

After molding to Near-Net-Shape, Hi-Tech uses CNC mills and lathes to improve component tolerance or achieve geometries you cannot create with injection molding alone.