Better Products for Less

About Us

Over 30 years ago Bill Kristensen Sr. started Hi-Tech, with the goal to create a full service facility that could support customers from mold builds, molding, machining and all post molding/machining operations. We have developed proprietary manufacturing processes for high-temperature molding, thus becoming a unique resource for cost-effective metal substitution. We are experts in advanced thermoplastic materials, our service model is stronger than ever.

Hi-Tech Talk

Moving to an Outside IT provider

IT’S ELECTRIC: EMI/RFI Shielding in Thermoplastics

Core Competencies

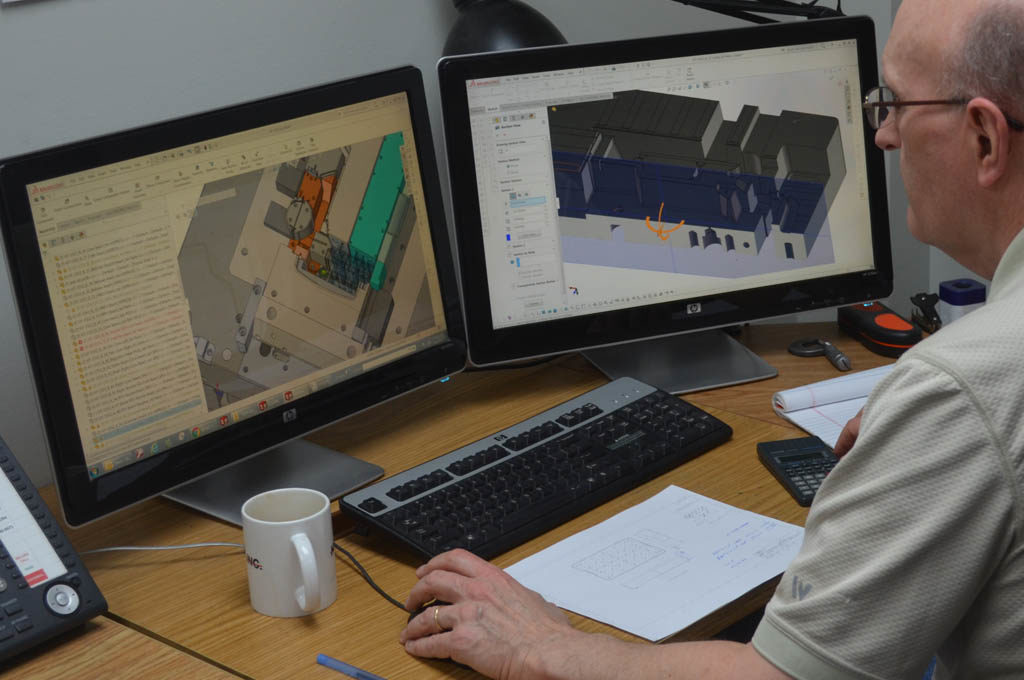

Thermoplastic Part

& Mold Design

Hi-Tech can evaluate 3D Models and 2D Prints to help optimize the Part Design for Molding and to help identify potential issues.

Learn MoreInjection Molding Thermoplastic Components

Hi-Tech has a long history of molding High Temperature, Heavily filled Engineered Thermoplastics.

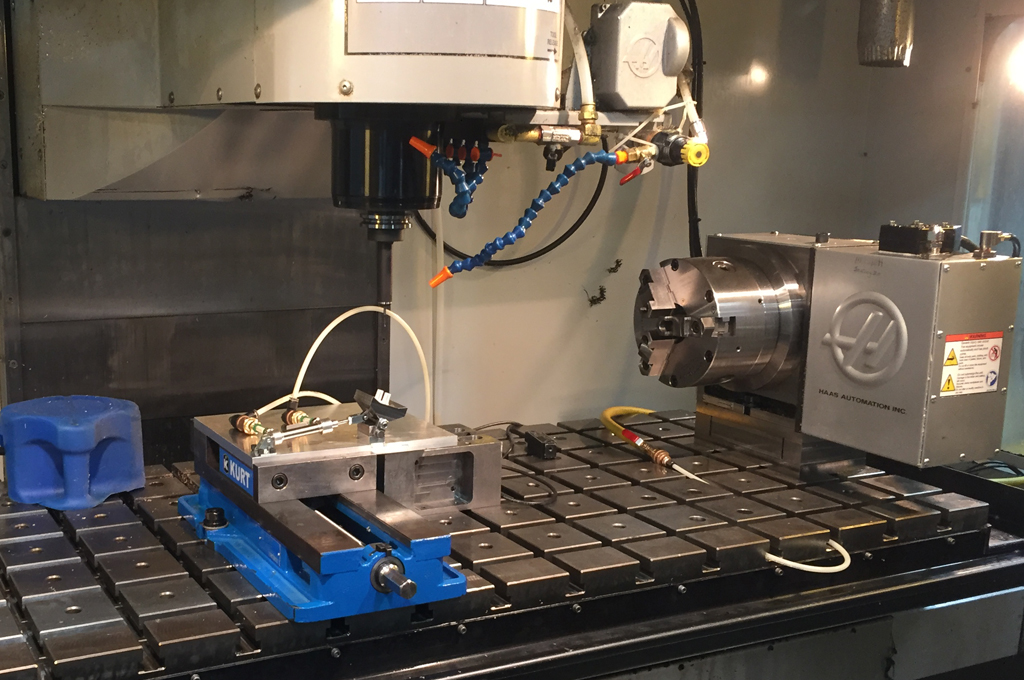

Learn MoreMachining Thermoplastic Components

Hi-Tech’s Aerospace business has created a Thermoplastic Machining department that is unique in Injection Molding.

Learn MoreComponent Assembly & Testing

Hi-Tech has developed assembly and testing processes for a wide range of configurations & industries.

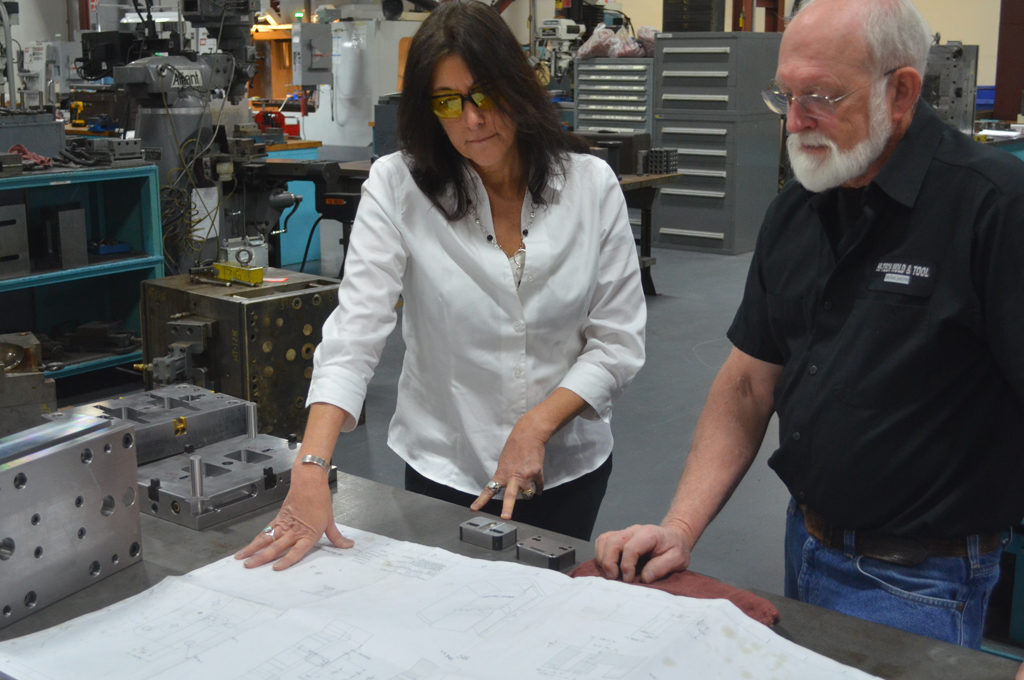

Learn MoreMold Building & Maintenance

Hi-Tech produces molds in-house and can source molds from Overseas. The tool room allows us to maintain consistent part delivery performance.

Learn MoreMaterial Expertise

Hi-Tech produces components and assemblies in a wide range of Engineered Thermoplastics, verifies lot traceability and can aid in material selection during design or supply issues.

Learn MoreOur Industries

Customer Focused. Quality Driven.

Contact the HT Engineering Team with Thermoplastic Part Design Questions.

Testimonials

I have been working with Hi-Tech for 5 years now. Over that span, Hi-Tech has always been very easy to work with and they present themselves in a professional manner. Hi-Tech has delivered quality injection mold tooling and parts with competitive pricing. Their Program Management and Engineering group kept up with several design changes throughout the tool build and still delivered on-time.

Hi-Tech has an excellent customer service and high quality products. Hi-Tech supports us with our Kanban program to have product on time. Support team is always available for us to answer all our questions.