Tonnage Calculator

Hi-Tech’s Clamp Tonnage calculator was created to help individuals answer the question of “How big of an injection molding machine will be required to mold my part?” This calculator simply uses the old rule of thumb of 2 to 4 tons/square inch.

The tonnage required to keep a mold closed during the injection phase is based on the projected area of the part. Enter the length, width and cavitation in the calculator to get two values that will bracket your required tonnage. Remember that the calculator uses projected area instead of straight surface area. If there are cut outs in the part where there is no plastic, the total surface area must be reduced by the size of those cut outs. You may need to make minor adjustments to your length and width to have the correct projected area appear in the calculator.

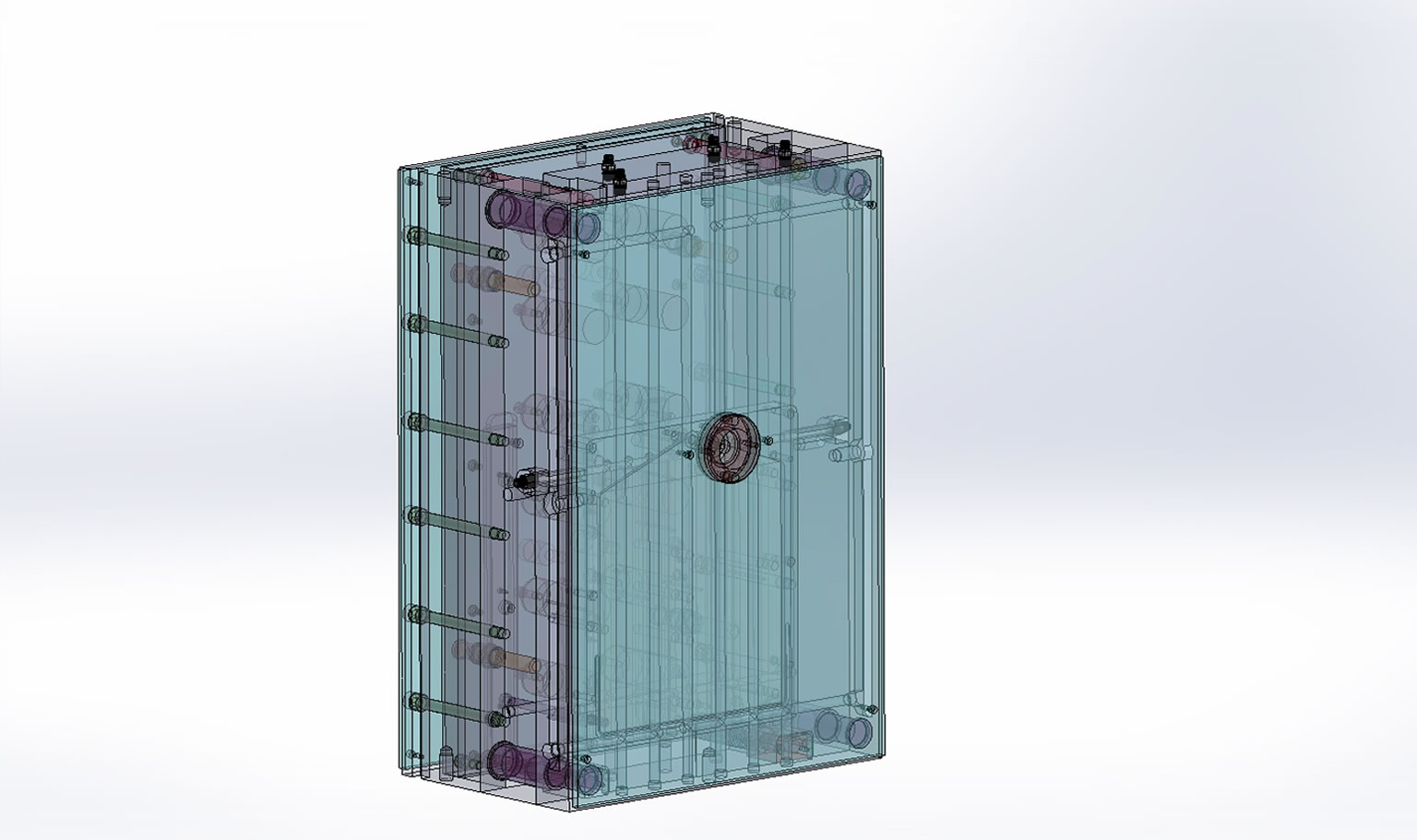

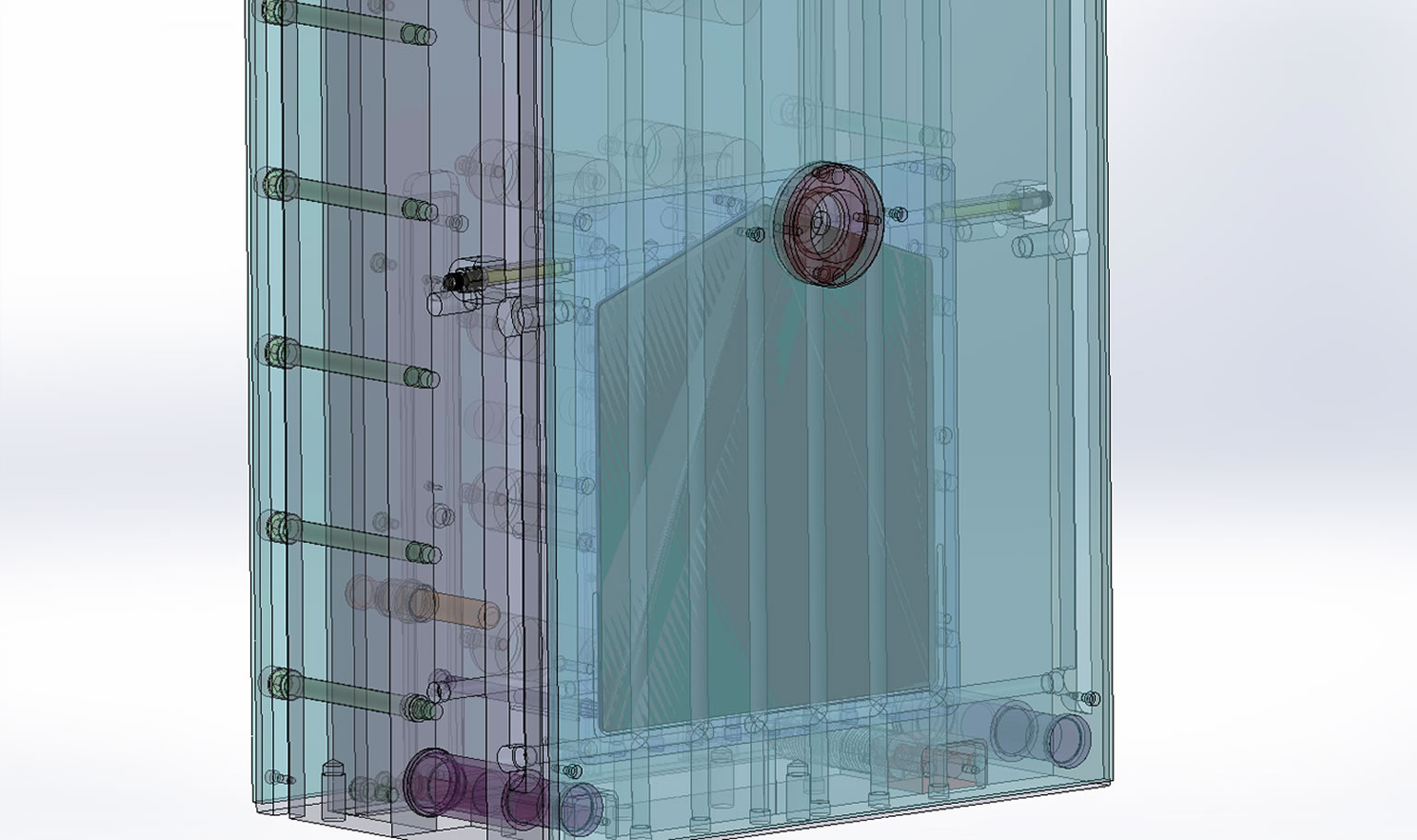

The example provided is a real part and real injection mold tool that Hi-Tech built. Hi-Tech has molded this 14”x14” plaque tool on a 450 Ton press. If you enter the correct information in the calculator below (14x14x 1 cavity), you’ll see the calculator brackets the machine that Hi-Tech actually uses to mold this plaque.

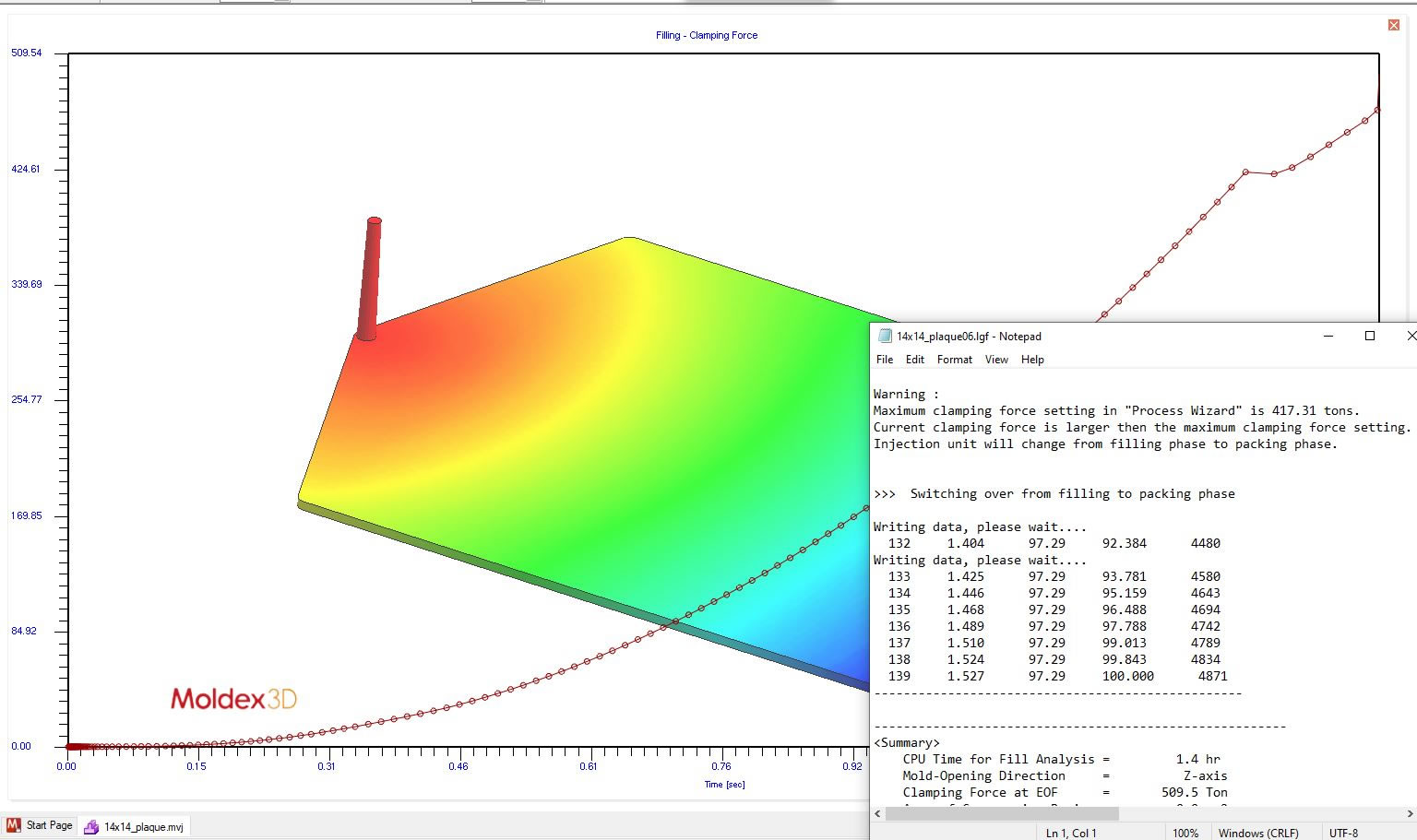

A mold flow simulation was run on the example part to determine various information during the design phase. As highlighted below, the simulation predicts a required tonnage of 509 Tons. You can see this on the simulation picture at the bottom of the text. This predicted value is also bracketed by the clamp tonnage calculator.

Click to enlarge.

Do you have feedback or questions about this tool?

Contact Us and we’ll respond quickly.

We know tooling like nobody else!