There are three major elements in thermoplastic design. Each is an opportunity to improve production efficiency, end-product performance and quality.

The first opportunity is part design, with material selection being a close second and mold design third. Optimizing the three plastic part design inputs – part design, material and mold design – are the best way to avoid issues. Experience in material and mold design in a given part geometry is perhaps the best advantage to achieve your goal of a good part. Unfortunately, issues can still arise after all three of these are set and the tool is built. All is not lost, however, though your options to optimize are more limited. When even the best-laid plans don’t create perfect parts, here are some issues to consider.

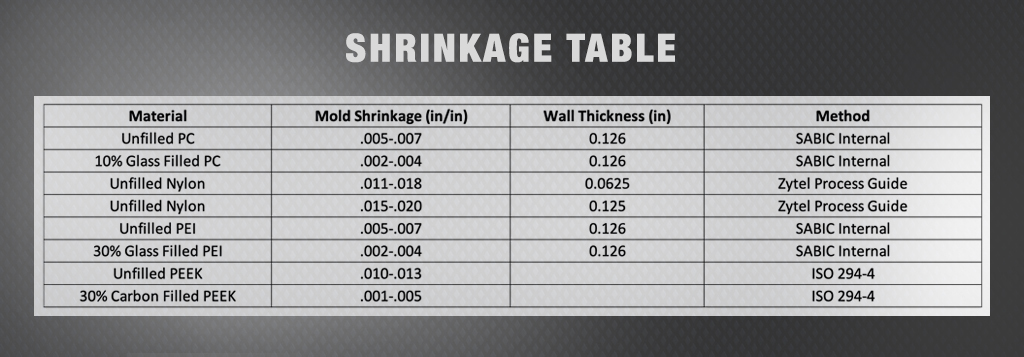

Compensating When Shrinkage Is More or Less than Anticipated

The most common issue once the tool is built and first samples are evaluated is the resin shrinkage used to design the tool resulted in a dimensional issue. If the part is too big, the shrinkage used was higher than actual. The part design, tool design and material combination result in a part that is not shrinking as much as anticipated. One option to help correct this issue is optimizing Mold Temperature and Pack Pressure to reduce the amount of material that goes into the part. Perform trials to reduce these variables until you get a short shot. If part is still too big, another option is to look for a similar resin that has a higher shrinkage than the one you are currently using.

If the part is too small, the shrinkage used was lower than actual. The part design, tool design and material combination result in a part that is shrinking more than anticipated. A fix that Hi-Tech uses successfully is adding a filler to the resin. Hi-Tech has added Calcium Carbonate to the resin to reduce the shrinkage. Process conditions can also increase the part size, such as increasing Mold Temperature and increasing Pack Pressure. Weighing parts created with varying process conditions can help determine if you are getting more material into the mold cavity – something you can alter to help reduce shrinkage.

Stop the Sink

Another common issue that can come up after the tool is built is an aesthetic issue called Sink – a localized portion of the part is sinking in or you can see a depression in the surface. Sink is caused by an adjacent wall being too thick. Figure 1 shows an example of a sink mark. In some cases, process changes, including increasing mold temperature and pack pressure can stop sink. If process changes do not eliminate the issue, you can add a chemical foaming agent to the resin. When processed correctly, the foaming agent will expand and offset the shrinkage in the thicker area. Sink marks can be avoided by making sure adjacent walls are only 70% of the wall thickness of the primary wall.

Proper Cooling Creates Consistency to Design

Another common issue when producing plastic parts is post mold warpage or shrinkage. Although tooling dimensions may be correct, when the part ejects, if the geometry is unstable, the part can shrink and warp creating dimensional issues. Some process changes may help reduce this, with increasing cooling time as the most common solution. Increasing the cooling time is similar to fixturing the part in the mold. Fixturing the part after it comes out of the mold is another common solution. The fixture should be designed to hold or even deform the part past the dimensions that are required to ensure final dimensions are correct.

Experience and Capabilities Optimize Tool and Molding Performance

Processing optimization, mineral fillers, foaming agents and cooling fixtures are a few of the ways to help improve your part after the tool has been built. Minimize the need for intervention before the tool design is frozen and the build has begun. Fully utilize all sources of information to plan the build and prevent problems by optimizing the part design, material and mold design. If you’ve encountered challenges like these – or any molding challenges – hit “Contact Us” and tell us what’s happening. We’ve got the experience and resources to help you build better parts.