Plastic parts can crack or fail for a variety of reasons. The part could be deformed beyond the mechanical properties of the material causing yield or break issues. Breakage can be characterized by brittle and and ductile mechanical failure. Brittle will typically show a sharp break and ductile will stretch and tear which may include stress whitening. Besides mechanical load based failures, UV may negatively decrease plastic performance over time. Parts may yellow and then crack due to UV exposure. The UV light attackss the polymer bonds

Another common mechanism for parts cracking that this article will focus on, is chemical attack also referred to as Environmental Stress Cracking (ESCR). This is one of the most common reasons for parts cracking, but the cause is not as obvious as other mechanisms for parts cracking.

The sunglasses pictured at the top of the article were purchased on the internet and were less than $20. The sunglasses began falling apart in only three weeks. The thin section of the frame above the lens was cracking in multiple locations each splintering in multiple directions. These parts weren’t cracking due to mechanical load.

These parts cracked in an incredibly short amount of time due to exposure of a chemical that was not compatible with frame material. The chemical was suncscreen. The level of exposure wasn’t immersion, but it was heavy contact. The parts were not under constant stress or load, but the first area to fail was the thinnest section of the frame. The top thin section of the frame failed before the bottom thin section of the frame because the top section was closest to the sunscreen.

The variables that may have an impact on the level or speed of chemical attack are: Temperature, Stress or Load, the Chemical itself and the concentration of the chemical. Some material suppliers perform extensive testing and have matrix of their materials against a variety of chemicals that are present in the industries the suppliers serve.

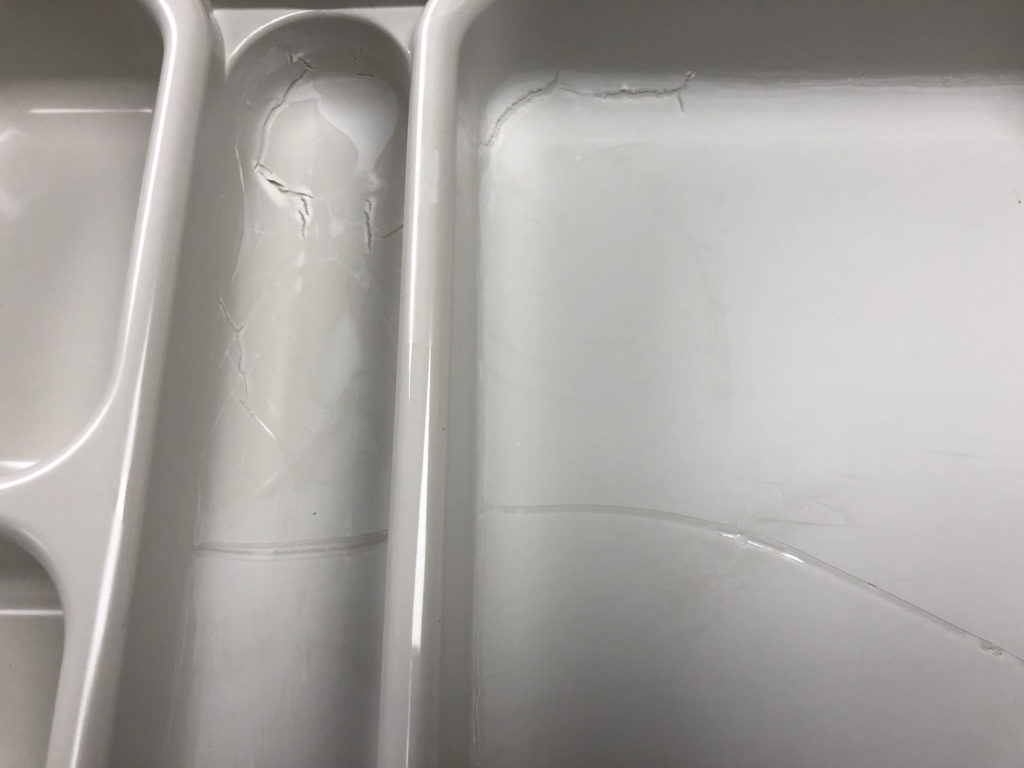

The picture at the bottom of the article is a Polycarbonate part that was exposed to Acetone and the cracks appeared in minutes. Often times, Chemical attack is a very slow process that you never see occurring. If you are concerned about chemical attack and you can’t wait for your results, there is a way to speed things up. You can increase the rate of reaction of the chemical attack by raising the temperature or increasing the concentration of the chemical

Medical device manufacturers will perform a heat aging test on a fully assembled device. They may put it in an oven at 150F for days or weeks. If any material in the device was not compatible with another material, the heat aging test would allow them to see it in days rather than months. Sometimes silicones that aren’t fully cured can attack thermoplastic parts based on minor off gassing.

If you have any questions about chemical attack (ESCR) on thermoplastics or other reasons parts are cracking, please post a comment or send us an email using Contact Us. Thanks for reading.