The aspect of thermoplastics that I’ve always thought is the most interesting is the ability to make thermoplastics more functional. Most thermoplastic applications that are older than 10 to 15 years are applications that utilize thermoplastics as a shell or protective package. Old and new desk telephones use thermoplastic as the shell, as do most portable electronics.

As the technology for putting new additives into resin or thermoplastic grew, the market acceptance of the thermoplastics with new fillers grew slower. Thermoplastics were what you made the box out of, not what went into the box. Thermoplastics were the outer shell, but did not have functional jobs inside boxes. Glass fiber is probably the most common additive for thermoplastic and it just made your shell or box stiffer and stronger. Talc or mineral filler was commonly used to reduce the amount of warpage in your shell or box. The same is true for flame retardant additives. They made your box adhere to UL flammability requirements.

It wasn’t until I learned about Teflon (PTFE) as an additive to improve the lubricity of a thermoplastic or Barium Sulfate to improve the radio opacity of a material that thermoplastics got much more functional for me. Why make your box out of PC/ABS and then use an EMI coating, when you can use PC/ABS with stainless steel fiber to attenuate EMI issues. One of the bigger trends that took thermoplastics into a more functional job was the use of Long Glass filled Polypropylene to replace metal in automotive. The skeletal structure that comes from producing components in Long Glass Fiber gave much improved strength to glass filled Polypropylene.

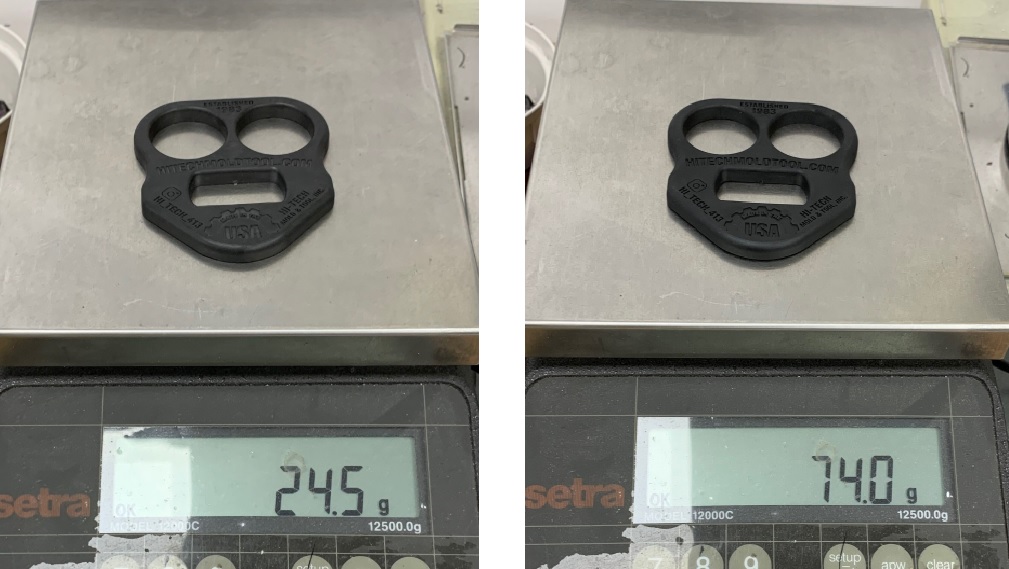

The feature image for this brief write up shows two different Hi-Tech bottle openers. The opener on the right was produced from recycle material from our Aerospace business. The specific grade we mold is RTP 2285HF. This makes for a very light and very stiff bottle opener. Recently a firearms manufacturer started selling a pistol lower produced from Tungsten impregnated Nylon. As Hi-Tech wanted to show we knew about this functional attribute, we partnered with our friends at Conventus Polymers to make openers in a material that had a specific gravity of 4.0. That material was Duramide PA6 HI HSG T40 BK.

If you want to give your plastic part the weight of metal, just add tungsten powder. If you want to give your plastic part the strength of metal, just add carbon fiber. Injection moldable thermoplastics offer fast cycle, complex geometry and way more function than that old plastic skin that covers your PC.

Thanks for reading and if you have any questions, please drop us a line via Contact Us.