Hi-Tech Mold & Tool, Inc. has our own tool room, so we quote tools that we make. When our customers request it, we’ll work with off shore tooling vendors but Offshore Tool Quotes and Domestic Tool quotes are not the same. Below we’ll outline some differences that we’ve experienced over many years of building and sourcing tools.

The cost of an Offshore Tool is less expensive than a Domestic Tool. Make sure when comparing cost that you include all costs necessary to get what you want. Generally, You are interested in getting a tool to produce parts, so you need to include the cost of shipping for both types (Offshore vs Domestic) and any duties associated. In 2019, a 25% Duty on Injection Mold Tools was implemented and then eliminated later in the year. At the time of writing this article (May of 2020), the 25% Duty is back and it is an additional cost that must be included in the comparison. Ocean shipping versus Air shipping must also be included in the cost comparison. For a smaller mold (approx. 1500 lbs), the Ocean freight cost should be around $700-800 and medium sized molds (approx. 3000 lbs) will be around $1000-1200. Air freight varies from $3-5 per pound, thus a smaller mold could cost as much as $7500 to ship via Air. Ocean freight will generally run 6-9 weeks and Air freight should run 2-3 weeks. Generally, there is no significant freight cost or lead time on Domestic tools.

Offshore tools are less expensive and they are that way because they are built in less time and the amount paid the tool makers is less. Often times, Off shore tools trade speed and cost for quality. The impact to quality is relatively less when it’s a simple mold that makes a simple part. As the part complexity goes up and thus the mold complexity goes up, the impact of the Offshore tool trade off on quality also goes up. OEMs with a lot of experience in purchasing tools for molded components will even separate what can be quoted off shore and what must be made at a Domestic tool maker. The impact of quality generally results in added time and cost. Hi-Tech has received off shore tools with a varying degree of work required to fix these quality issues. Whomever receives the off shore tooling needs to be capable of fixing tooling issues.

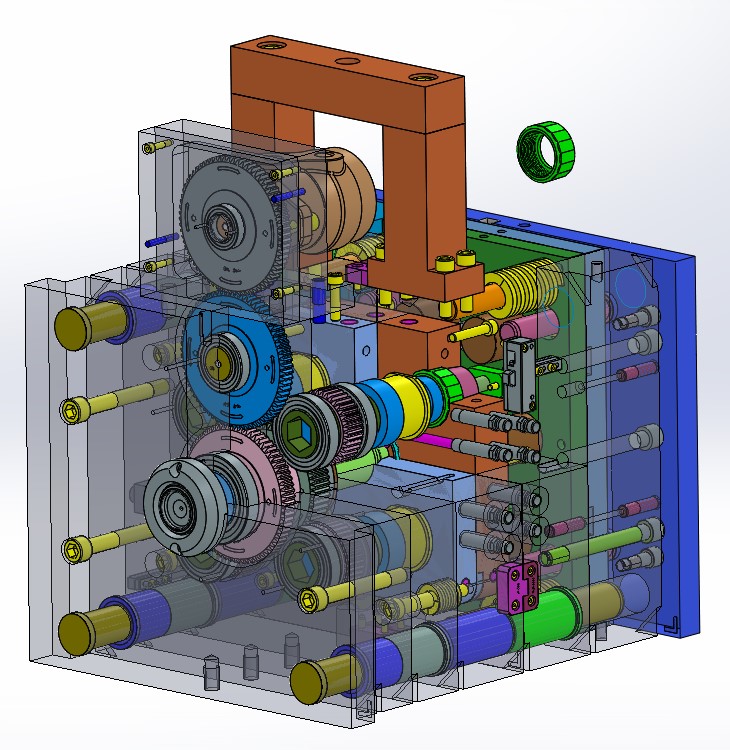

No matter where the tool is made, It is good to understand how readily the tool can be fixed in the event of an issue. This starts with good documentation of the tool design. A 3D model should be available from either Offshore or Domestic Tool makers, but you need to make sure you have a digital copy of the design. The complexity of the tool and the source for all of the parts is another aspect of making sure you can fix it. Gears, hydraulic cylinders and hot manifolds are all more complex aspects of tools that mark a difference between Off shore molds and Domestic molds. Replacement parts and wear items will be harder to replace in off shore molds.

Training and equipment are also areas the can impact tooling produced in Off Shore tool shops versus Domestic tool shops. As this can vary, the best way to manage the impact of these is to be informed. At Hi-Tech, Dave, Brian, Scott, Dan, Jeff and Ryan are well trained and continuing to train. They are experts in their areas and cross train to improve in others.

Off Shore and Domestic tools can result in successful programs as long as you know what to expect. Dealing with a US based vendor that works with off shore tool manufacturers can help to reduce the communication gap and ensure less is lost in translation. If you need help making plastic parts or injection molding tools, go to Contact Us on the menu bar or call Hi-Tech at 413-443-9184.

Thanks for reading and let us know if you have any questions.