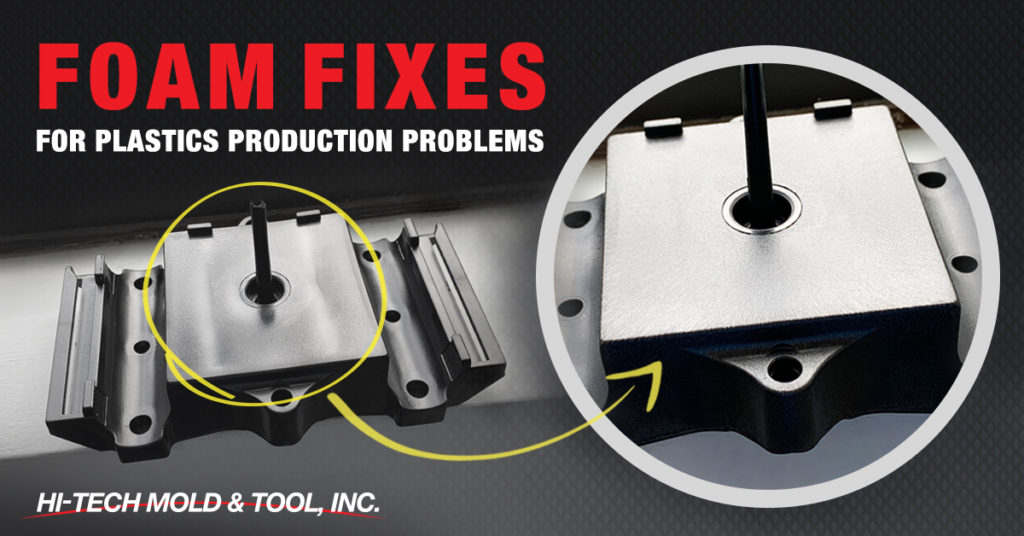

Thermoplastics have a lot of good attributes, but they aren’t perfect. Thicker ribs or walls will show sink marks. Surfaces can show the signs of minor impacts or scuffs.

Larger parts with thicker sections require longer cycle times to ensure there is no part deflection upon mold opening. When part designs result in molding issues, chemical foaming agents can be an effective tool to improve the finished product.